Utilizza la maniglia al centro dell’immagine per spostare il divisore.

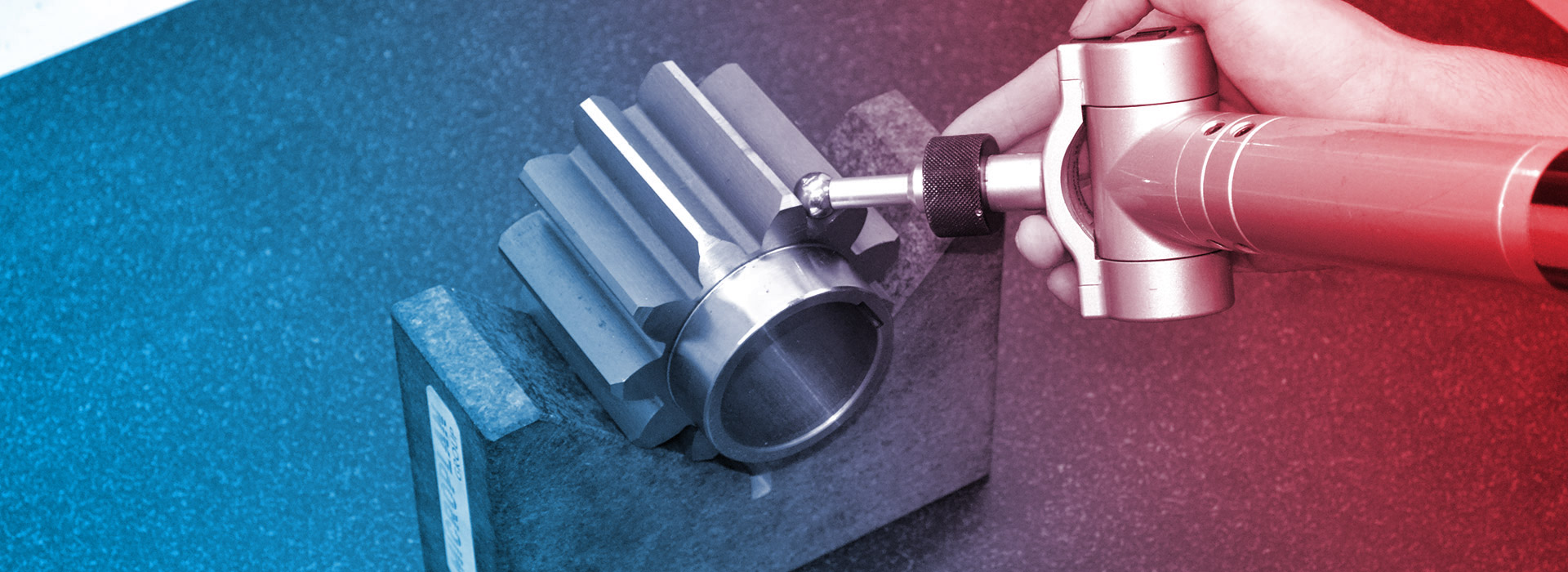

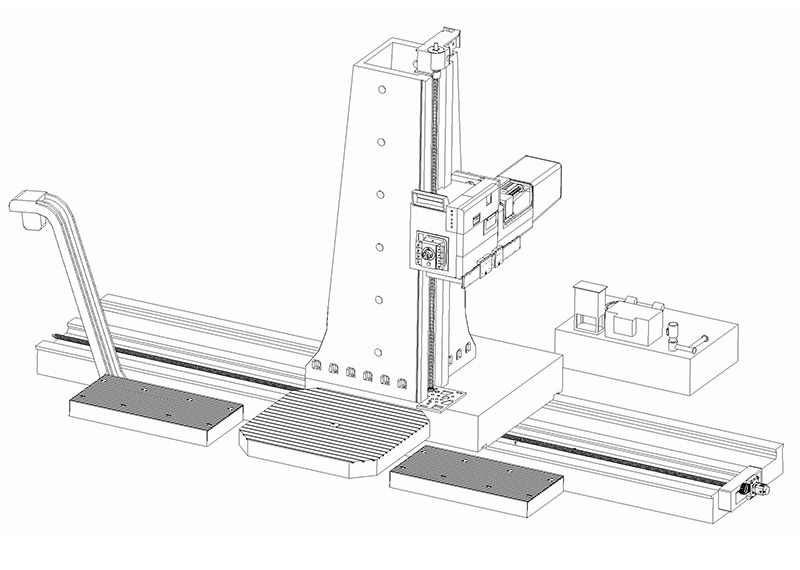

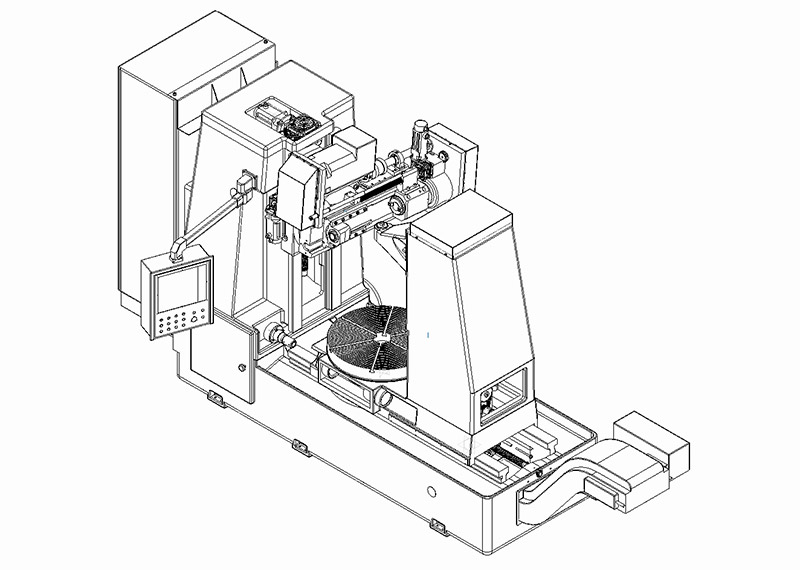

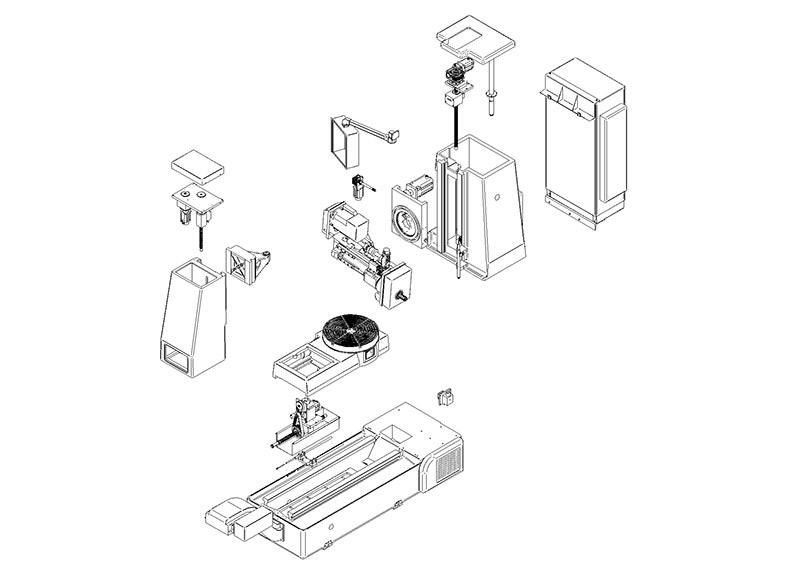

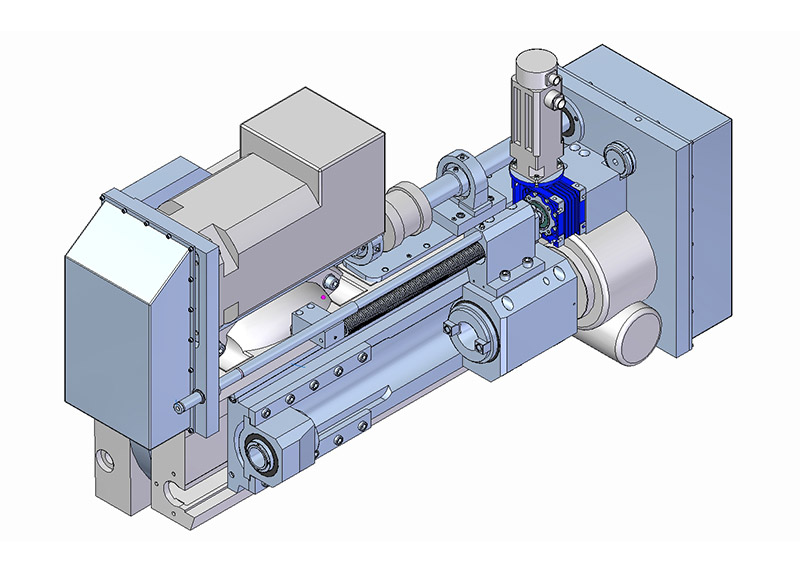

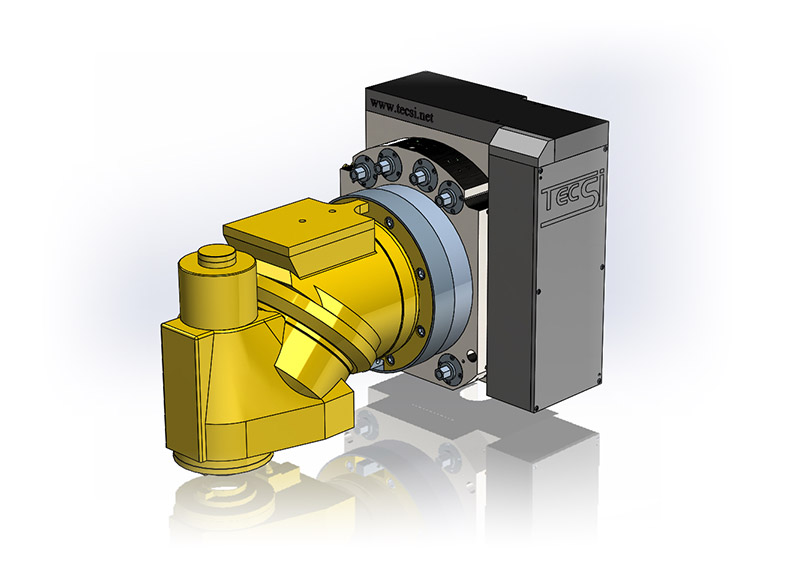

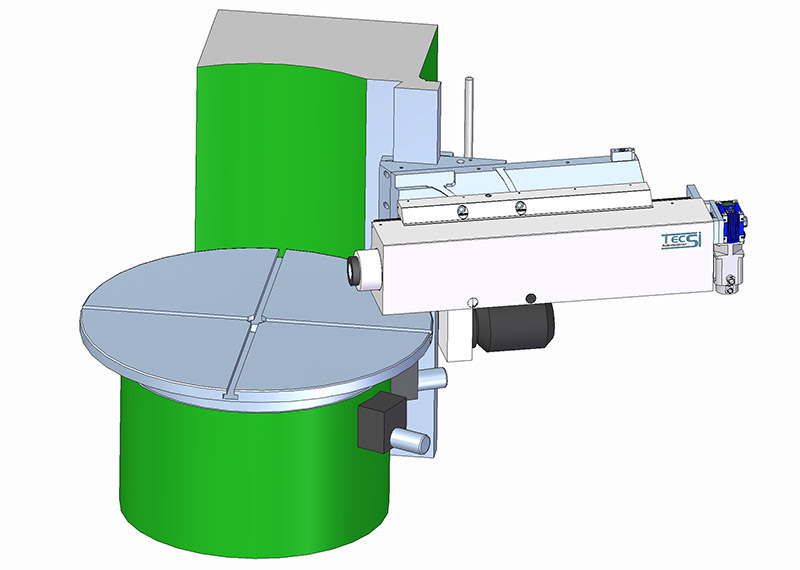

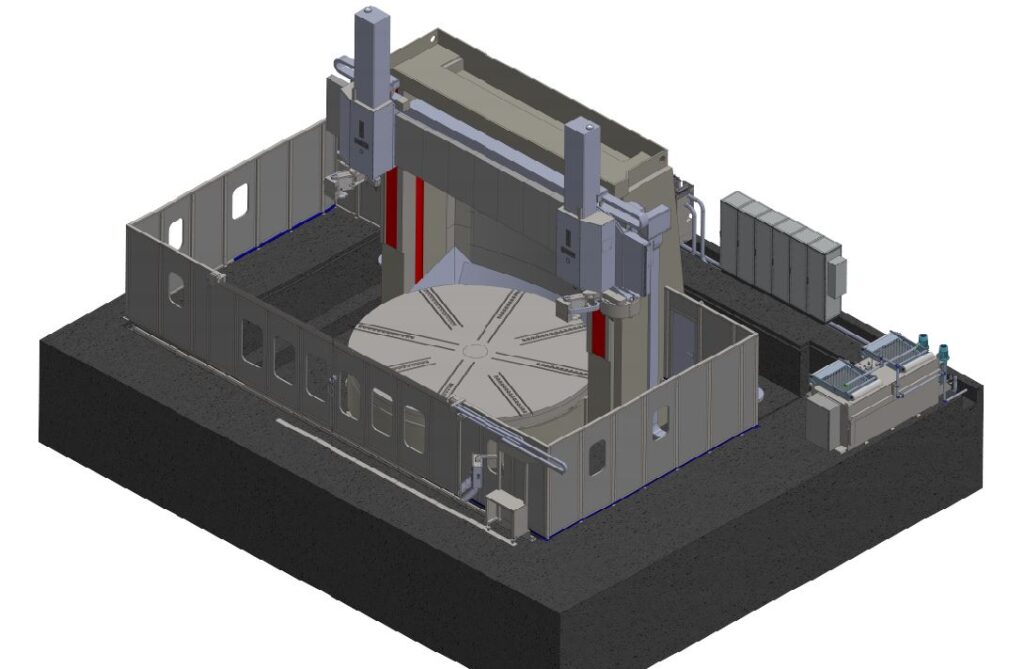

Tutti i componenti vengono progettati internamente ed affidati a collaboratori esterni per la realizzazione.

La parte elettrica è interamente realizzata all’interno dell’azienda, dalla stesura dello schema alla realizzazione del quadro.

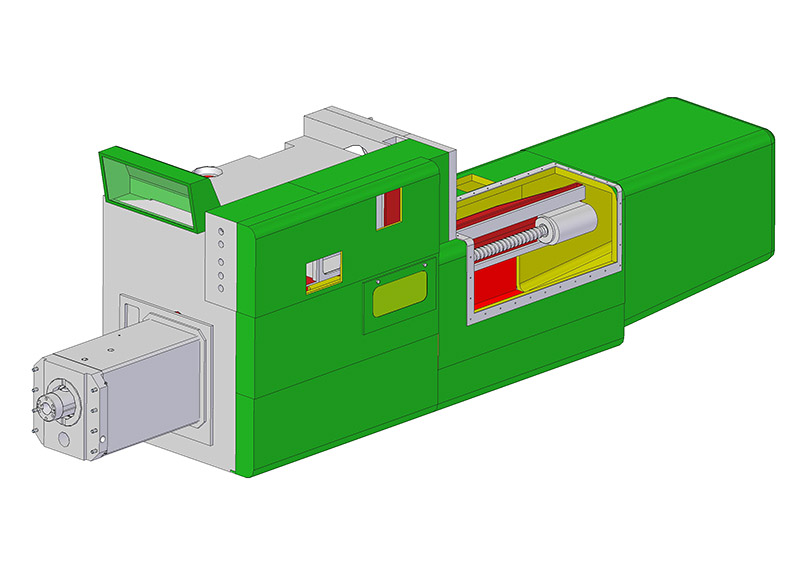

Realizzazione dal nuovo di carterature per ogni tipo di esigenza ed adeguiamo quelle esistenti alle normative. Implementiamo la sicurezza con sistemi di visione ad hoc.

Stesura fascicolo tecnico, manuali di uso e manutenzione, documentazione completa e dettagliata a corredo della macchina

Tel: 030 7241110

Fax: 030 7242807

Via Borsellino 68

25038 Rovato (BS)

Ufficio: Lun-Ven. 8-12, 14-18

Officina: Lun-Ven. 8-12, 14-18

Necessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information.

Any cookies that may not be particularly necessary for the website to function and is used specifically to collect user personal data via analytics, ads, other embedded contents are termed as non-necessary cookies. It is mandatory to procure user consent prior to running these cookies on your website.